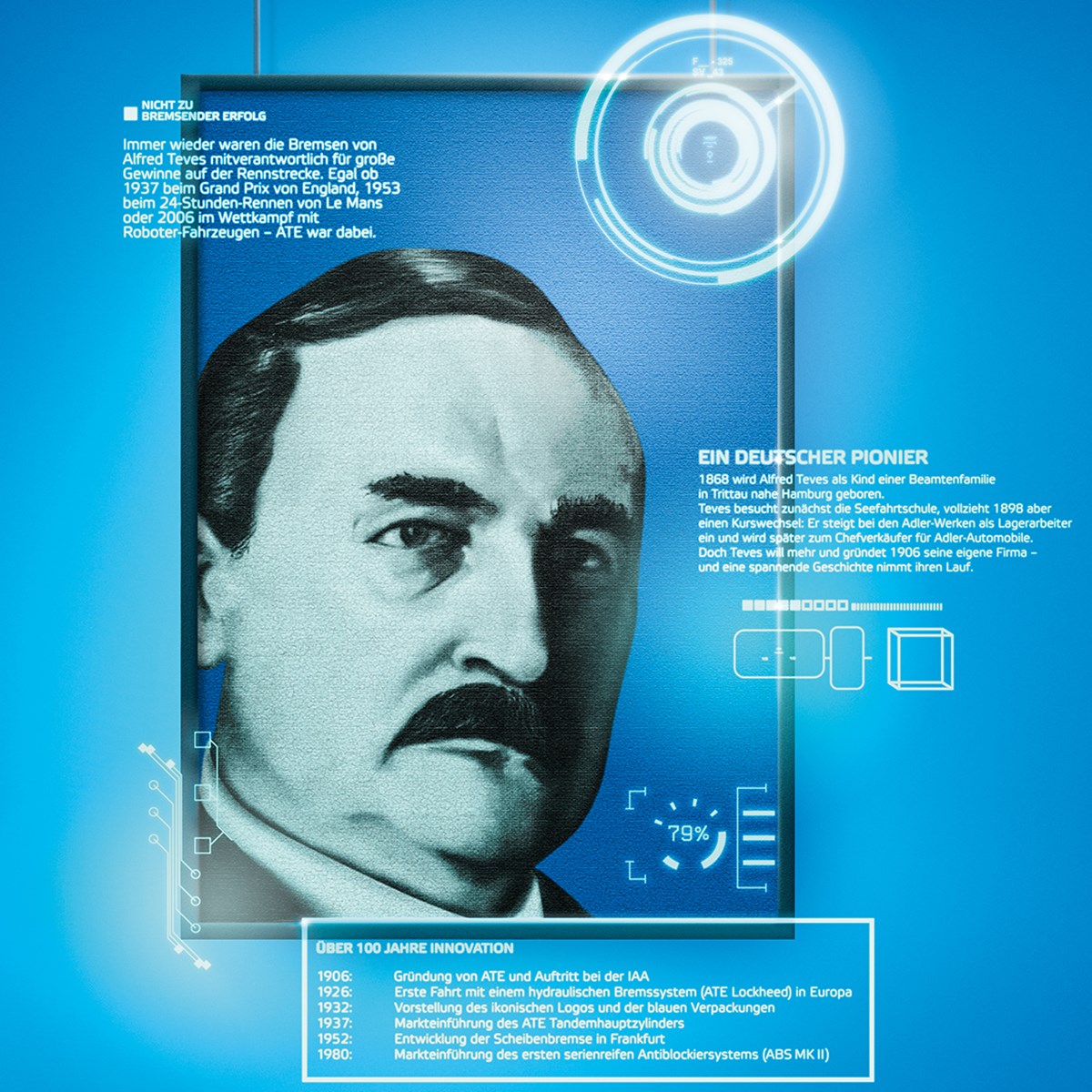

ATE history

ATE – our development

100 years of success are not enough for us

From the hydraulic brake to ABS, ATE has enriched the market from the outset with pioneering developments – and it will continue to do so.

Never-ending Story

The ATE success story is not over yet, however, because we’re still the leading pioneers thanks to the innovations we continually introduce – and we’ll be blazing a trail in the future too!

2016

ATE presents the first Mercedes brake disc aftermarket solution for the C and E Classes at leading trade exhibitions.

2010

The innovative, low-dust ATE Ceramic brake pads are presented to the public, as is the ATE Classic product range.

2006

The further development of the 2FNR-VEVO FNR calliper is introduced to the market.

2005

The new, special low-viscosity ATE SL.6 brake fluid is optimally matched to the hydraulics of electronic braking systems like ABS and ESP®.

The Continental technology for hybrid drives passes its stringent series of tests in the GMC Silverado.

2002

Presentation of ESP® II – the first ESP® with active steering intervention opens up new dimensions of driving dynamics and stability.

1998

The Brake and Chassis Group of ITT Industries is sold to Continental AG and Continental Teves AG & Co. oHG is founded. R&D is expanded in the strong partnership of the Continental Group and new markets are opened up.

1996

A new brake disc revolutionises the market – the PowerDisc minimises fading and has a considerably longer service life thanks to its score-free, uniform abrasion. Its premiere takes place at the Automechanika 1996.

1984

Series production of the first integrated ABS in the world is launched – the ATE ABS MK II is used by Ford USA and Ford Europe and a quarter of a million ABS systems are delivered within the next two years.

1980

The ABS MK II – the first anti-lock brake system from Teves to attain full readiness for volume production.

The product philosophy of ATE is that safety systems must be affordable – and that in itself will increase the individual and overall degree of driving safety.

1979

The ATE floating calliper disc brakes are introduced in high-performance, touring motor sports. They are used in the BMW M1 in the Group 4 version.

1977

A pioneer on principle – Teves is one of the first suppliers to open up works for its customers in North America. In 1977 it begins manufacturing floating calliper disc brakes and vacuum brake boosters for Ford and Volkswagen in its Culpeper, Virginia factory.

1972

The Teves plant in Rheinböllen supplies high-performance ATE four-piston fixed-calliper brakes for the Ferrari 365 GTB road model and for the Porsche 911 S.

Successful in-house development – the first booster developed wholly in house by the company. The ATE T52 vacuum booster goes into volume production in 1972 and the production figures have remained impressive to this day.

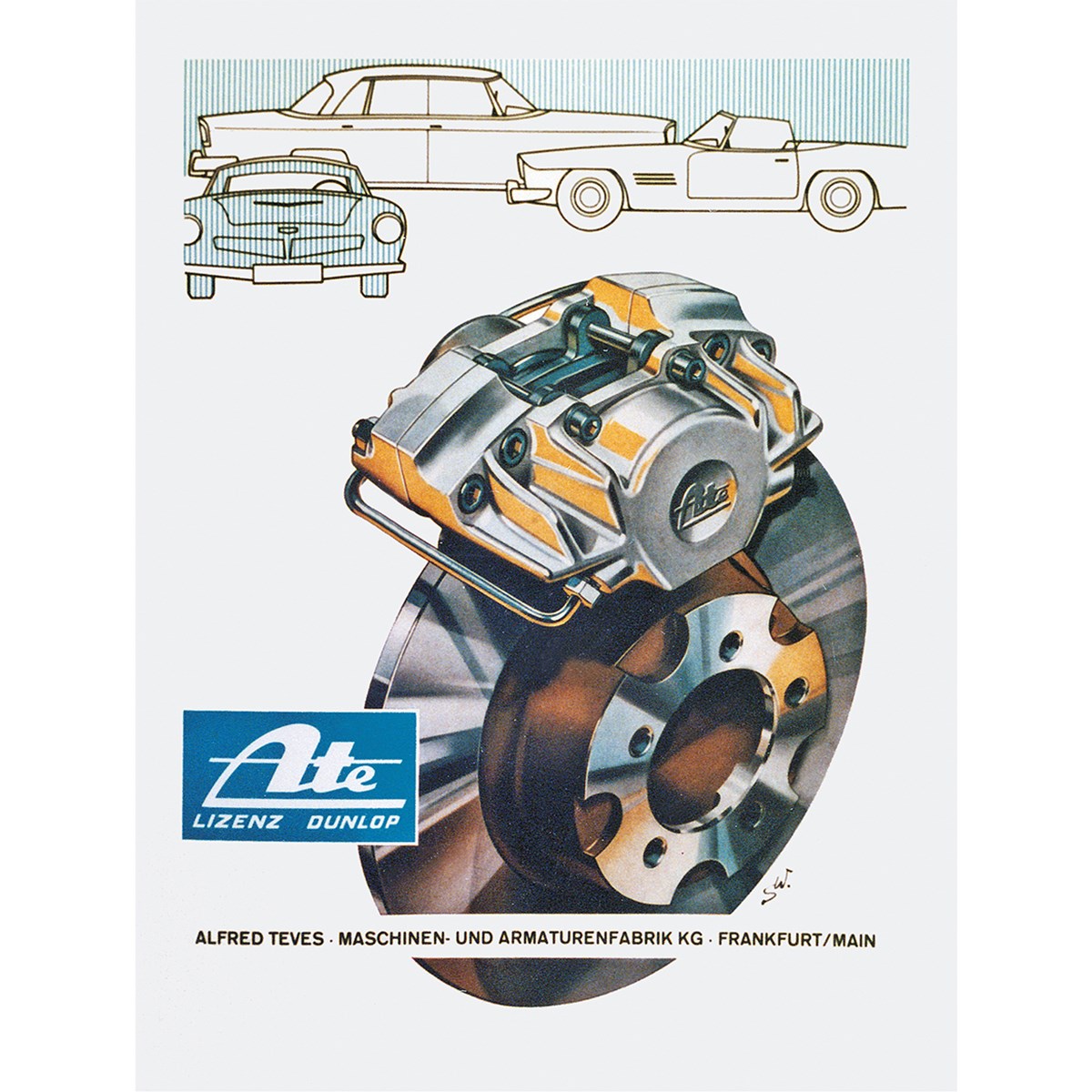

1960

ATE takes over the manufacture of disc brakes in its Frankfurt factory under licence from Dunlop.

The Ford 17M, nicknamed the “bathtub”, was a big seller in the 1960s. It was supplied with ATE Dunlop disc brakes for a surcharge of 150 marks.

1958

ATE patents the design principle of the “negative scrub radius” for improved directional stability during braking. In the same year, ATE starts mass production of disc brakes in Germany.

1954

The ATE pump circulation brake boosters are the first hydraulic brake boosters to be used in car racing – in the legendary Mercedes-Benz Silver Arrow.

1952

Teves realises at an early date that disc brakes are technically superior to drum brakes and development work begins in Frankfurt in this year.

1948

Despite most of the main factory in Frankfurt and other workshops being destroyed during the Second World War, the company has again achieved its former size with 3,500 employees. A new factory in Gifhorn underlines the intention of continuing to place the main emphasis on the development of hydraulic brake systems.

1939

The production of cylinder liners and ribbed cylinders using centrifugal casting begins in the Frankfurt am Main factory.

1937

The ATE tandem master cylinder is introduced for cars, trucks and buses.

Bernd Rosemeyer and Manfred von Brauchitsch take first and second places at the British Grand Prix – and their racing cars are equipped with ATE brakes.

1934

In their racing cars for the 750 kg formula race, Auto-Union and Daimler-Benz use ATE brake systems optimised by Teves for use in motor sport.

1926

The Adler Standard is the first car on the continent to drive with a hydraulic braking system – and it’s the ATE Lockheed brake. ATE improves its market position thanks to innovative technical developments and new kinds of casting processes.

1921

The letters of the ATE brand name replace the former logo of piston ring, fist and hammer. The blue packages soon become known to workshops and companies as top-quality products.

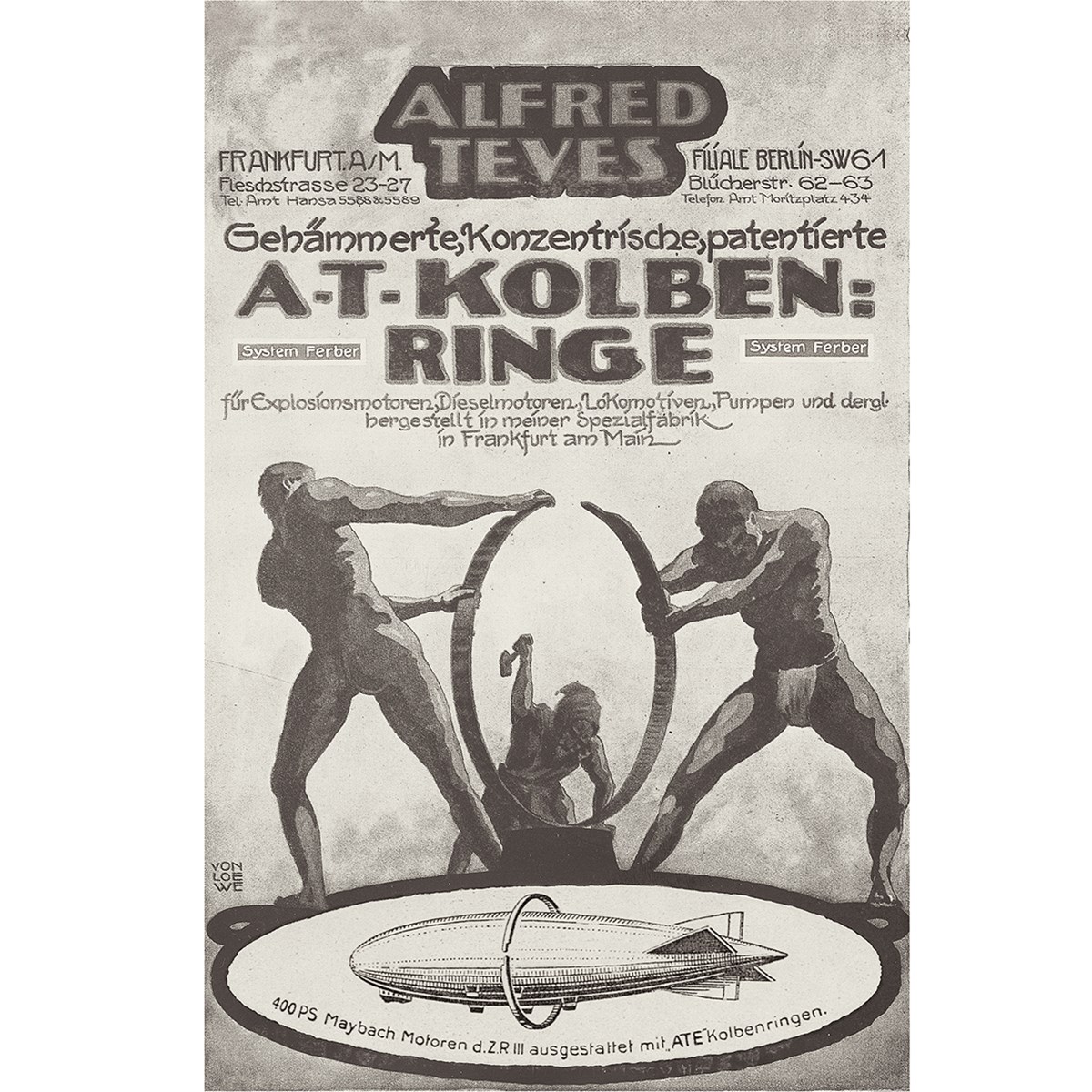

1911

The Alfred Teves Maschinen- und Armaturenfabrik is founded. After the end of the First World War, parts made in-house become increasingly important. The company makes a name for itself on the automotive parts supplier market with high-quality piston rings and braking systems.

1909

Teves founds the Mitteldeutsche Kühlerfabrik (Central German radiator factory) together with engineer Matthäus Braun. The company wins Audi, Wanderer, Hansa and other important manufacturers of the time as customers.

1906

Alfred Teves founds the company as a general representative for automotive accessories and presents his products at the IAA in Frankfurt.